School of Management Studies, Karpagam College of Engineering, Coimbatore

An industrial visit to AKR INDUSTRIES PVT. LTD., Tirupur, was successfully organized by the School of Management Studies, Karpagam College of Engineering on Tuesday, 08th July 2025. A total of 42 students, accompanied by two faculty members — Mrs. K. Kavitha and Mrs. Gayathri N. — participated in the visit with the objective of gaining practical knowledge about production activities, management processes, and technological operations in the manufacturing sector.

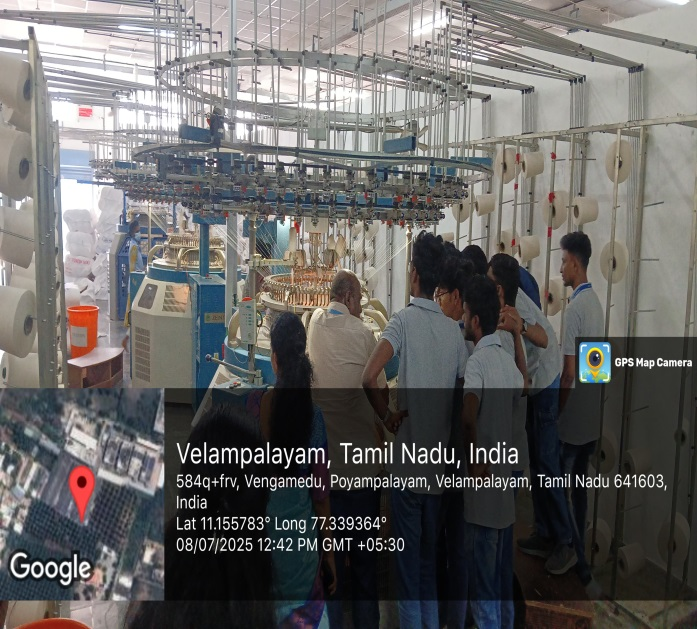

The students and faculty traveled by the college bus, which departed from the campus at 9:30 AM and reached the company premises at 11:00 AM. Upon arrival, necessary security checks and documentation procedures were completed. The students were then taken to the production department, where they were given an orientation on the safety rules and operational guidelines to be followed within the factory premises.

Company officials provided a comprehensive overview of the production processes, including insights into the machinery used, workflow systems, and technology implementation in their operations. The visit offered the students a valuable opportunity to relate theoretical knowledge to practical industrial applications.

The visit concluded at 2:00 PM, and the team departed the company to return to the college.

This one-day industrial visit served as an enriching experience for the students, helping them to enhance their understanding of industrial practices, improve their practical knowledge, and prepare themselves for future careers in management and industry.

Section-Wise Observations:

1. Printing Unit:

The visit commenced at the Printing Section, where students were introduced to two categories of machines:

- Automatic Machines:

These machines required minimal manpower (2 to 3 persons). Variants such as 13-color and 8-color printing machines were observed. Automation reduced both labor and time consumption significantly. - Manual Machines:

These machines were labor-intensive, needing 7 to 8 people per unit. Manual printing processes were slower and required more coordination, offering a contrast to automation.

Other machines present included:

- Curing Machine

- Fusing Machine

These played crucial roles in finishing printed garments.

2. Embroidery Section:

A dedicated, automated Embroidery Section was visited next. Two types of embroidery were demonstrated:

- Type 1: A sponge layer is used and later removed after embroidery.

- Type 2: Embroidery is directly attached to the cloth without any removable layer.

The section reflected precision and modern embroidery technology.

3. Cutting Section:

In this section, fabric was measured and cut into required shapes and sizes using special tools. Workers wore metallic gloves as a safety measure to avoid injury from sharp machinery.

4. Stitching Section:

The Stitching Unit followed the printing process. This area was highly modernized with:

- LED display boards showing the number of clothes to be stitched, packed, and pending tasks.

This streamlined workflow and enhanced productivity.

5. Packing Section:

The final garments were sorted by size and client order, and packed systematically. The packed items were then dispatched to domestic e-commerce clients such as Amazon, Flipkart, and Meesho.

Conclusion:

The visit concluded with an interactive session. The General Manager shared practical insights on garment exports and global trade. The Owner of the company delivered a motivational speech, sharing tips and entrepreneurial advice which inspired the students greatly.

Highlights and Outcomes:

- Enthusiastic participation and engagement by MBA students.

- First-hand exposure to industrial operations, automation, and management practices.

- Understanding of workflow integration from fabric cutting to packaging.

- Motivation and entrepreneurial insights from industry leaders.

- Enhanced knowledge of technology, labour distribution, and client handling.